|

Abstract摘要

大家都熟悉戴尔的供应链,大家都认为戴尔的成功与其供应链运作模式直接相关。但对诺基亚的供应链了解的人并不多,事实上,诺基亚长期以来一直主宰着全球手机市场,这主要归功于其供应链。本文对诺基亚供应链进行了全面、系统、动态的实证研究。基于供应链理论,分析了公司的整体竞争优势和竞争策略。此外,我们还从动态和进化的角度研究了诺基亚的供应链。本文根据供应链过程,从采购战略、制造战略、渠道战略、客户服务战略等实际阶段和战略模块,对诺基亚的供应链进行了全面的描述。

本文在研究了供应链管理策略的基础上,简要分析了诺基亚供应链管理中存在的问题。根据对诺基亚供应链管理策略的研究成果,提出了相应的建议和改进方法。

Everyone is familiar with Dell's supply chain, and everyone agrees that Dell's success is directly related to its supply chain operation mode. But not many people are familiar with Nokia's supply chain,In fact, Nokia has long dominated the global mobile phone market, largely due to its supply chain. This paper makes a comprehensive, systematic and dynamic study to demonstrate of Nokia supply chain. Based on the supply chain theory, we analyze the company’s overall competitive advantage and competitive strategy. Besides, we also study the Nokia supply chain from a dynamic and evolutionary perspective. According to the supply chain process, this paper comprehensively describes the Nokia’s supply chain, from the practical stage and strategy module, such as purchasing strategy, manufacturing strategy, channel strategy, customer service strategy.

After studying the supply chain management strategy, this paper also makes a brief analysis of the problems in Nokia supply chain management. According to the research results of Nokia supply chain management strategy, corresponding suggestions and improvement methods are proposed.

1. Introduction介绍

20世纪90年代以来,物流与供应链研究在学术界和商业界都非常流行。提出了许多著名的概念和理论,探索了许多经典的优秀供应链实践案例。然而,大家都熟悉戴尔的供应链,大家都认为戴尔的成功与其供应链运作模式直接相关。但很少有人熟悉诺基亚的供应链。大多数研究都局限于一些已知的早期案例,如北京“星园模式”等,对诺基亚供应链的全面、系统和动态研究还相对较少。本文试图对供应链及其管理理论进行一些充实。

本文以移动通信产业的发展为背景,以供应链及其管理理论为基础,以诺基亚的供应链为研究对象,从理论和实践上全面、系统地研究了诺基亚供应链战略及其演变。Y,经验性和动态性(Christopher,2016年)。首先,综合分析是指供应链过程,尽可能全面描述诺基亚的供应链。其次,系统分析是基于竞争优势理论和供应链理论。分析公司的整体竞争优势和竞争战略,研究公司在不同发展阶段的经营战略转型。第三,运用更多的实证证据。本文试图通过对不同时期诺基亚供应链的实证研究,来研究诺基亚的供应链。最后,动态意味着供应链是不固定的。要不断探索总结经验,发现不足,及时学习更多成功的供应链案例,弥补不足。

Since the 1990s, logistics and supply chain research has been very popular in both academic and business circles. Many famous concepts and theories are put forward, and many classic excellent supply chain practice cases are also explored. However, everyone is familiar with dell's supply chain, and everyone agrees that dell's success is directly related to its supply chain operation mode. But few are familiar with Nokia's supply chain. Most of the studies have been limited to a few known earlier cases, like Beijing "star garden model" and so on, comprehensive、systematic and dynamic research on Nokia supply chain is still relatively few. This paper tries to make some efforts to enrich the supply chain and its management theory.

Based on the development of the mobile communication industry and Based on the supply chain and its management theory, taking Nokia's supply chain as the research object, this paper attempts to study Nokia supply chain strategy and its evolution in theory and practice comprehensively, systematically, empirically and dynamically (Christopher, 2016). First of all, comprehensive analysis refers to the supply chain process, as far as possible comprehensive description of Nokia's supply chain. Secondly, system analysis is based on the competitive advantage theory and supply chain theory. Analyze the overall competitive advantage and competitive strategy of the company, and study the business strategy transformation of the company in different development periods. Third, apply more empirical evidence. This paper tries not to limit itself to a few earlier cases that are already known, but to study Nokia's supply chain with more empirical studies in different periods. Finally, dynamic means that the supply chain is not fixed. We should constantly explore and summarize our experience, find out our shortcomings, and timely learn more successful supply chain cases to make up for our shortcomings.

2. Nokia background

Nokia Corporation is a multinational company headquartered in espoo, Finland, specializing in the production and related services of mobile communication devices. Nokia was founded in 1865, mainly engaged in logging and papermaking, and gradually expanded into the fields of rubber shoes, tires and cables. Later, it developed into a mobile phone manufacturer, focusing on the research, development and authorization of basic communication services and advanced technologies (Nokia Corporation , 2018).

On February 11, 2011, Nokia and Microsoft reached a global strategic alliance and deeply cooperated to develop the Windows Phone operating system. Faced with the rise of smartphones with new operating systems, Nokia's position as the world's largest mobile phone seller was surpassed by samsung in the first quarter of 2012, ending 14 years of market dominance. On September 3, 2013, Microsoft announced that it would acquire Nokia's devices and services division for 5.44 billion euros and obtain the relevant patents and brand authorization. In the future, Nokia will strive to develop Here map services, solutions and networks (NSN) and three pillar businesses of leading technology. On April 25, 2014, Nokia announced the completion of the mobile phone business transaction with Microsoft and the sale of the device and service business to Microsoft. On November 18, 2014, Nokia officially released the first Android tablets, after Nokia will be committed to the mobile network infrastructure, software and services, surveying and mapping navigation and intelligent positioning, advanced technology research and development and authorization. On November 18, 2015, Nokia officially launched its $16.6 billion acquisition of alcatel-lucent. On May 18, 2016, Nokia brand was authorized to be manufactured by HMD and fuzhikang under honghai group. Nokia's progress has been inextricably linked to its sound supply chain management strategy.

3. Nokia supply chain strategy and its evolution

Based on the supply chain theory, especially the analysis framework of supply chain strategy, focusing on Nokia's supply chain strategy practice and its evolution, Analyze how they contribute to the competitive advantage of enterprises in cost reduction and service enhancement. First, analysis from Nokia's supply chain practice in different periods in general and modularize the supply chain strategy. Then each strategy module is analyzed and discussed in detail.

3.1 Nokia supply chain evolution and strategy module

In the context of economic and technological development, Along with the development of enterprises, the supply chain practice of any enterprise is a process from primary to advanced, from partial to whole, from imperfect to mature (Handfield, 1999). Although the process is complex and often crisscrossed, in view of the general principles of organizational design and business management of enterprises, the construction and management of supply chain usually implement modularization, overall division of labor (Chopra, 2015). Nokia supply chain practice can be divided into four stages with the development of enterprises. That is, focusing on functional stage, internal integration stage, external integration stage and end-to-end integration stage. According to the supply chain process, Nokia's supply chain strategy module can be divided into procurement strategy, manufacture strategy, channel strategy, customer service strategy, and end-to-end supply chain structure, supply and demand plan and information management.

Stage 1: focus on functions. The functional departments of enterprises focus on improving their own processes and improving resource utilization. The department manager usually focuses on the cost and functional performance of the department. The process of cross-functional departments is not well understood, which limits the operation efficiency of complex supply chain processes. Obviously, it is not enough to focus on local performance optimization. Long-term accumulation will lead to big problems. Nokia's 1995 operating crisis has to do with the failure to address supply and demand globally and collectively.

Stage 2:Internal integration. The enterprise has defined the process and overall process of the cross-business department so that each functional department can clearly understand its role in the complex supply chain process. After the operation crisis in 1995, Nokia began to plan and reform its supply chain system from 1996 on a global scale, and took supply chain management as an important strategic measure.#p#分页标题#e#

Stage 3:External integration. Stage 3 extends Stage 2 supply chain management practices to customers and suppliers. The enterprise has identified the strategic customers and suppliers of the supply chain, and can cooperate with the strategic partners of the supply chain to share the key processes and data information needed to support the business process of the enterprise.

Stage 4:End-to-end integration of supply chain. Customers and suppliers work together to develop mutually beneficial strategies and real-time performance goals that are compatible with each other: using IT to automatically integrate cross-enterprise business processes to support supply chain strategy. This is the advanced stage of supply chain management, which requires long-term unremitting efforts.

As can be seen from the above stage of Nokia's supply chain practice, with the development of economy and technology, the scope of supply chain is expanding. The number of partners in the supply chain is increasing, and the length and difficulty of management of the supply chain are also increasing. This requires enterprises to keep pace with The Times, integrate themselves into the supply chain, constantly innovate themselves, keep up with the needs of The Times, and then make progress. As can be seen from the above four supply chain practice stages, this is exactly what Nokia does.

3.2 Supply chain structure, supply and demand planning and information management

The design of the supply and demand network, the formulation of plans and the management of information combine the entity resources and information. Jointly drive supply chain execution at the planning level (Sarkar, 2017). If something goes wrong at the planning level, for example, the design of physical network is unreasonable, the accuracy of supply and demand planning is low, or the processing and transmission of supply and demand information in the supply chain are seriously distorted, Adverse effects and consequences are quickly seen at the execution level. It can be said that a good supply chain is above all determined at the planning level.

3.2.1 Nokia supply chain structure

Nokia has been improving and strengthening its ability to design and manage supply networks and to build its own supply networks in the light of the growing and changing mobile industry. Nokia's strategy in the supply chain structure is to rationally set up and allocate global resources, and ensure that it strives to increase the added value of its products on the basis of cost leadership, so as to meet the requirements of customers in various markets. For example, the establishment of the factory in 2006, India is highly advantageous to make use of local favorable policies and human and land resources to reduce operating costs, at the same time satisfy the growing Indian market demand.

3.2.2 Supply chain supply and demand planning and information management

Overall, the Nokia supply chain supply and demand planning information management system provides a set of business measures in a modular form. The module includes almost all the business functions required by the supply and demand network, and connecting users to technical applications to form a comprehensive system, for strategic and day-to-day management of the company (Bozarth, 2016). The core of this is how to create, communicate, execute, and manage supply and demand plans. Nokia's overall supply and demand plan is based on the advanced concepts of SOP (Sales and Operation Planning). Make full use of modern information technology, such as material requirements planning (MRP). Material Requirement Planning, Enterprise Resource Planning, Advanced Planning and Scheduling, Supply Chain Planning and other reasonable structures. The supply chain supply and demand planning system strongly supports the daily and weekly planning and implementation activities. Effectively ensure the production and customer delivery accuracy, the whole system with good functionality, integration, flexibility, and openness (Mangan & Lalwani, 2016).

3.3 Supply chain purchasing strategy

The purchasing strategy of the supply chain plays a prominent role in the mobile phone manufacturing industry, even as the core competitiveness. It has the first impact on the cost of products and the sustainability of manufacturing. Because phones have so many and complex components from communication chips to transceivers to batteries, it cannot be made by a single manufacturer,it is necessary to streamline all aspects of the supply chain and maintain close cooperation with suppliers so that they can truly become part of themselves. Not only that, for multinational companies, it needs to balance the internationalization and localization procurement. Take into account the requirements of cost and market response speed, and adopt effective best supply chain practices as far as possible, such as e-purchasing, iHUB, VMI, etc.

3.3.1 Strict supplier selection

Quality and cost have always been the focus of businesses, and Nokia, as a world-class company, is no exception. In terms of procurement, Nokia has put good quality first through strict supplier selection. And rely on large-scale localized procurement to reduce costs. Nokia has to evaluate multiple aspects of all its suppliers, such as quality, production operation, supply chain, product development and design process, product responsibility, plant facilities, environmental management and risk management. And strictly operate in accordance with the universal procedures and standards.

Nokia's global procurement system is used in every Nokia mobile phone manufacturing base around the world, and supplier development and material quality are managed by global organization CQTM. In this way, Nokia has extended its quality monitoring and management to the supplier sector, pushing suppliers to provide spare parts, raw materials and other parts in line with Nokia's strict quality standards.

3.3.2 International procurement

International procurement refers to using global resources to find suppliers around the world. Look for the best quality and reasonable price products (goods and services). Most of the electronic components used in Nokia's mobile phone production are purchased internationally. Since electronic materials are generally standard materials, the demands of nine mobile phone factories in the world are combined that can form a strong negotiating force in purchasing and gain the price advantage. As a result, Nokia has reduced its procurement costs and increased its operations in terms of supply. This is a typical example of a cost competitive advantage achieved through centralized and large-scale procurement.

3.3.3 Local procurement

Nokia implements localization purchasing strategy, mainly assembly and packaging parts. The localization purchasing strategy has saved a lot of transportation costs, greatly reduced the cost of Nokia products and shortened the delivery time. It is convenient for timely feedback of information and can gain the price advantage, so as to help Nokia gain a firm foothold in various markets.

3.3.4 Vendor production is clustered

Under the development trend of economic globalization, it is an important factor to determine whether an enterprise can stand out from the competition whether it can keep track of market changes in time and meet customers' individual needs. The establishment of Beijing star network (international) industrial park has enhanced Nokia's rapid response capability. Being able to face unpredictable demand changes in a leisurely manner and effectively reduce supply chain links is conducive to frequent small batch delivery. Its overall operation mode is a typical enterprise cluster based on supply chain. On the one hand, it can reduce the internal manufacturing cost; on the other hand, it can reduce the transaction cost between enterprises, and gain the competitive advantage in cost as a whole.

3.3.5 Effective VMI inventory strategy

Nokia has built an iHUB near each plant. And bring all suppliers together into a single data platform, enterprises have realized the sharing of logistics demand and supply information. Through this information platform, suppliers can query the inventory status of the logistics center in real time. Adopt automatic replenishment system, according to Nokia production material consumption situation timely replenishment,and the process becomes more transparent. Supported by advanced information network systems, with Nokia as the core, the visibility of the supply chain is significantly enhanced. The overall inventory of the supply chain decreases the cost, so the competitiveness of the whole supply chain is improved.

4. Supply chain customer channel strategy

4.1 Build a variety of three-dimensional distribution system

Generally speaking, different market segments require different supply chain processes, assets, channels, supplier relationships and performance evaluations. Therefore, together with pricing Strategy, supplier financial policy, promotion Strategy and other trading terms and conditions, the Total Channel Strategy is formed. And multi-level marketing channels have not caused the increase in product prices, because Nokia also adopted direct supply to achieve flat channel construction. In today's transition to an Internet company, Nokia is also actively practicing and innovating online sales and sales model of flagship experience stores.

4.2 Build excellent sales logistics

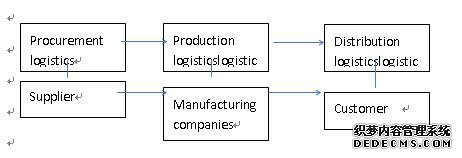

As is known to all, logistics is an indispensable and important activity in modern business. At Nokia, its logistics activities run through the end-to-end process, as shown in the chart below:

#p#分页标题#e# #p#分页标题#e#

Nokia believes that building superior sales materials is a long-term process. Enterprises should study how to design logistics models and know how to enhance the transparency of products in circulation channels so as to manage channel inventory well with customers. In building these capabilities, it is important to listen and analyz customers' needs,provide efficient and flexible solutions to customers' plans.

4.3 Supply chain customer service strategy

Customer service strategy is also the basic configuration element of supply chain strategy and is indispensable. Nokia is strengthening its ability to meet customers' needs and enrich its services, and it can bring users a direct experience. At present, Nokia customer service organization is implementing its new generation customer service supply and demand network around the world according to the established road map. With the change of global economic environment and the transformation of corporate strategy, Nokia's customer service supply and demand network and the overall supply chain strategy should also keep pace with The Times.

Generally speaking, enterprises that can gain a leading position in the future market must be the cost leader and service leader. And the management of logistics and supply chain can give full play to enterprise capability. On the one hand, material flow from raw materials to customers is planned and coordinated as an integrated system. At the same time, we should make full use of modern information technology to strengthen the links between marketing, network system distribution, manufacturing process and purchasing activities. Only in this way can we achieve better service at lower cost. Nokia's success shows that this can be done.

5. Exist problems

In an increasingly competitive global market, The product life cycle is getting shorter and shorter, and the number of products expands rapidly. Customers have higher requirements for delivery time and expectations for products and services. In this context, supply chain management emerges at the historic moment. Supply chain management utilizes modern information technology to build collaborative business partnerships with suppliers and customers by transforming and integrating business processes, thus greatly improve the competitiveness of enterprises. The market competition in the 21st century is no longer the competition between enterprises, but between supply chains.

5.1 lack incentive to innovate

Nokia's share price has slumped in recent years, hit hard by apple and Google in high-end smartphones. In the middle and low end of the market with the competition with domestic mobile phone manufacturers, it can be said that the enemy on the stomach. Although Nokia has maintained more than 40 per cent of the global handset market and a higher share of the smartphone market, it has lost its incentive to innovate. In terms of technological innovation, Nokia has lagged far behind apple.

5.2 Product, r&d, marketing strategy and enterprise development strategy problems

The current mobile phone development trend cannot be followed on the product, the screen is small and the mobile Internet is weak. In research and development, Europeans cannot quickly launch products in the face of changes in the mobile market. In terms of enterprise development strategy, although the transformation of OVI and Internet has been announced, it has not been fully prepared, mainly because the mobile phone platform cannot carry such an Internet plan.

5.3 Problems in the supply chain

Nokia faces the challenge of the traditional supply model and the supply chain is too long. High inventory cost and high inventory risk; Slow market reaction; the logistics transportation cost is too high (the air transportation proportion is high), the application procedures are complex and so on. As the number of spare parts purchased every year is very large, supply management becomes the core issue of manufacturing and cost control.

6. Supply chain advice for Nokia:

6.1 Strict supplier selection and localized procurement

Quality and cost have always been the focus of business attention. Nokia, a world-class company, is no exception. In terms of purchasing, Nokia needs to take good quality first through strict supplier selection and rely on large-scale localized procurement to reduce costs.

6.2 Effective inventory strategy

Nokia needs to centralize all its suppliers to a single data platform, and information is shared between businesses. It can query the inventory status of Nokia in real time and adopt the automatic replenishment system. Supported by advanced information network systems, with Nokia as the core, the visibility of the supply chain is significantly enhanced. The decrease of the total inventory of the chain reduces the cost, so the competitiveness of the whole chain is improved.

6.3 Respond quickly to changing customer expectations

Build strategic partnerships to increase customer satisfaction can enable core enterprises to accurately and timely understand the needs of end consumers through distributors.

6.4 Quick response to the market

In order to respond to the market quickly, in addition to accurately grasping the market demand, it is also necessary to ensure the close cooperation between enterprises at all nodes and realize the seamless connection of the supply chain. This requires strategic partners to have expertise to respond quickly to downstream needs.

6.5 Reduce supply chain uncertainty

To reduce the uncertainty of strategic partnership in the supply chain, enterprises need to trust each other. Both demand information and supply information can be shared on the supply chain through the information system.

6.6 strengthen partnerships with enterprises

In the process of cooperation, Nokia and its partners should focus on the competition strategy and conduct extensive cooperation in product r&d, supply management, quality management and production planning;Through to the personnel, information and process integration and optimization of the configuration, fundamentally improve the production, research and development, management and resource use efficiency, thus greatly enhance the core competitiveness of the Nokia and its partners ─ ─ collaborative supply chain competitiveness.

6.7 Adopting the direct supply model

On the one hand, it is beneficial for Nokia to grasp more accurate information of end-user demand. On the other hand, by reducing the level of distribution channels, the distribution cost can be reduced and the efficiency of the supply chain can be improved.

7. Conclusion

A new era has come. The scientific and technological revolution has led to the high integration of knowledge and economy. Nokia's rival is not only a Samsung, SONY Ericsson, MOTOROLA these traditional mobile phone maker, added more Apple, research in motion (RIM), such as the mobile phone industry new entrants, and Microsoft, Google, yahoo, these coveted croc mobile software and Internet services.

In the increasingly fierce competition in the background, for Nokia, only the building combines the Internet, media, mobile phone mobile terminal and its solutions, to consolidate the supremacy in the field of mobile phones. This is a challenge and an opportunity for Nokia to keep itself ahead of the new era by rapidly and appropriately changing its supply chain. Nokia can only improve its supply chain management and transform and integrate its business processes with modern information technology, and establish collaborative business partnerships with suppliers and customers, to improve the competitiveness. The market competition in the new era is no longer the competition between enterprises, but between supply chain and supply chain.

8. Reference

1. Cecil Bozarth (2016), Introduction to Operations and Supply Chain Management, Global Edition, Pearson

2. Martin Christopher (2016), Logistics and Supply chain management, FT Publishing International

3. Nokia Corporation (2018) ,available at https://baike.so.com/doc/1237745-1309111.html [accessed on 9th June 2018]

4. John Mangan & Chandra L. Lalwani (2016), Global Logistics and Supply Chain Management, John Wiley & Sons

5. Robert B.Handfield (1999), Supply chain management, Prentice Hall

6. Sarkar (2017), The Supply Chain Revolution: Innovative Sourcing and Logistics for a Fiercely Competitive World, AMACOM

7. Sunil Chopra (2015), Supply Chain Management: Strategy, Planning, and Operation, Global Edition: Strategy, Planning, and Operation, Pearson

|

|

|||

| 网站地图 |